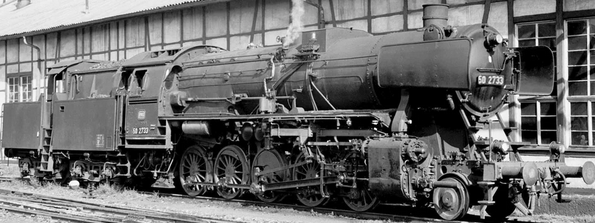

Today we will talk about the BR-52 locomotive. You can see the composition led by the BR-52 locomotive in the exposition of Museum of Technology Vadim Zadorozhny .

By the beginning of the war in 1941, the German locomotive industry had a sufficient supply of steam locomotives of various types and series. The main ones were BR44 and BR50

However, it soon became clear that they were of little use for waging war on the Eastern Front.

The German command had to face a number of problems. As it turned out, on the territory of the occupied Ukraine and Belarus, there was no necessary infrastructure to equip these steam locomotives with water, and a powerful partisan campaign unfolded in the forests deep behind enemy lines.

In the 1930s, in connection with the industrialization announced in the USSR, a new powerful commercial steam locomotive of the Felix Dzerzhinsky series was introduced on the Soviet railway network, which had a six-axle tender for a huge supply of water, capable of traveling many kilometers without replenishing the tender with water, under which it was laid the entire rail infrastructure.

The German steam locomotives of these types could not pass the huge hauls between our stations without replenishing water supplies. They needed quality maintenance and repairs. But where to get it if the German locomotive brigades were far from their depots and home bases?

It was extremely problematic to force the local population from the occupied territories to provide high-quality service to steam locomotives at gunpoint. And even more so, it was impossible to avoid sabotage due to hatred of the enemy, which was what the Soviet underground workers actually did.

At the end of 1941, the length of railways in the occupied territory of the USSR reached its maximum. Simultaneously with the rebuilding of the tracks to the Western European gauge of 1435 mm, the Germans were restoring what had been destroyed during the retreat by the Red Army, and the partisans were actually already waging a “rail war”, not without the help of frosts, which were unusually cruel in the winter of 1941-42. The German Wehrmacht was facing a transport crisis.

In December 1941, at a meeting, Hitler bluntly said: “No miracles of technology, simple machines are required that can withstand five years of operation!” That is, we need cheap stamped equipment to work for wear. In March 1942, the production of locomotives was placed under the control of the Minister of Armaments, Albert Speer. The first step of the newly created Main Committee for Rolling Stock was to reduce the production program, in which only BR 44, BR 50 and BR 86 remained (heavy and medium types and a tank locomotive). These models were simplified during construction. Since a locomotive was required that, with an axle load of 15 tons, could drive a train weighing 1200 tons along the plain at a constant speed of 65 km / h, they settled on the BR 50. This machine went through several stages of simplification, abandoned the water heater, large smoke deflectors, the second sandbox and etc.

The modified BR 50 steam locomotives went under the designation Übergangskriegslokomotive – transitional type. In six months, the “peaceful” BR 50 turned into a “military” steam locomotive BR 52. Of the 6,000 parts, about 1,000 were abolished altogether, and 3,000 were modified. The total consumption of materials was reduced by 26 tons, including the reduced consumption of non-ferrous metals from 2.8 tons to 150 kg.

Metal consumption is reduced to a minimum. The total weight of the locomotive could be further reduced, but then the new machine would not be able to cope with more or less heavy freight trains (due to the limitation of the traction force on the clutch). In the German press of those years, it was reported that the locomotive was made entirely of tin.

The production time was so reduced that the production of steam locomotives subsequently doubled, while the cost dropped markedly.

The locomotive has a powerful boiler, which has a steel firebox with a flat ceiling of the fire box – a combined Crumpton-Belper design, used on old locomotives. The locomotive is equipped with a Wagner-type regulator with large and small valves. The cone is single-hole, with a diameter of 150 mm, which is why it has a characteristic low exhaust tone. Grate BR 52 fixed, with cleaning hatch. Tilting inward, not quite comfortable, shurovochnaya door of the Marcotti system. The locomotive has a two-turn Schmidt superheater, two Ackerman safety valves with a drive to the booth for manually releasing steam, a purge valve on a Gestra-type grip sheet. On the left side are two horizontal Friedman-type injectors with a capacity of 180 l/min. The locomotives were equipped with steam-air compound pumps, driver’s cranes and Knorr triple valves. Round spools of the Karl-Schulz type, fixed, therefore there is a bypass valve for the unpaired course of the Winterthur system. External steam distribution mechanism of the Walschart-Geizinger system with an external location of the wings. The heads of the drawbars are made welded, which is why they often break. Part of the locomotives was built without box wedges. Box platbands made of textolite. Front trolley (runner) type Kraus – Helmholtz. Speedometer without Doit system registration. The booth is made closed on all sides, the connection with the tender is made of tarpaulin bellows. Under the seats and the floor is a steam heating coil. On the front sheet of the firebox there was a box for heating food. In the booth there is a Bosch system grease fitting for centralized lubrication. The locomotive has a 0.5 kW turbine generator. Buffer lights with dimming. Knorr system brake.

The locomotive has a powerful boiler, which has a steel firebox with a flat ceiling of the fire box – a combined Crumpton-Belper design, used on old locomotives. The locomotive is equipped with a Wagner-type regulator with large and small valves. The cone is single-hole, with a diameter of 150 mm, which is why it has a characteristic low exhaust tone. Grate BR 52 fixed, with cleaning hatch. Tilting inward, not quite comfortable, shurovochnaya door of the Marcotti system. The locomotive has a two-turn Schmidt superheater, two Ackerman safety valves with a drive to the booth for manually releasing steam, a purge valve on a Gestra-type grip sheet. On the left side are two horizontal Friedman-type injectors with a capacity of 180 l/min. The locomotives were equipped with steam-air compound pumps, driver’s cranes and Knorr triple valves. Round spools of the Karl-Schulz type, fixed, therefore there is a bypass valve for the unpaired course of the Winterthur system. External steam distribution mechanism of the Walschart-Geizinger system with an external location of the wings. The heads of the drawbars are made welded, which is why they often break. Part of the locomotives was built without box wedges. Box platbands made of textolite. Front trolley (runner) type Kraus – Helmholtz. Speedometer without Doit system registration. The booth is made closed on all sides, the connection with the tender is made of tarpaulin bellows. Under the seats and the floor is a steam heating coil. On the front sheet of the firebox there was a box for heating food. In the booth there is a Bosch system grease fitting for centralized lubrication. The locomotive has a 0.5 kW turbine generator. Buffer lights with dimming. Knorr system brake.

Part of the BR 52 locomotives had a bar frame with a thickness of 80 mm, the other part had a sheet frame with a sidewall thickness of 30 mm. The right and left cylinders, cast according to the same model, were interchangeable. The rear end of the carrier of the front bogie, made according to the type of the Krauss-Helmholtz bogie, was pivotally connected to the lower part of the crankcase, suspended on plain bearings between the inner shoulders of the front coupling axle.

Part of the BR 52 locomotives had a bar frame with a thickness of 80 mm, the other part had a sheet frame with a sidewall thickness of 30 mm. The right and left cylinders, cast according to the same model, were interchangeable. The rear end of the carrier of the front bogie, made according to the type of the Krauss-Helmholtz bogie, was pivotally connected to the lower part of the crankcase, suspended on plain bearings between the inner shoulders of the front coupling axle.

On steam locomotives, under-axle leaf springs are used for the driving wheelsets and over-axle leaf springs for the running wheelset. The springs of the runner and the first three driving wheelsets were interconnected by balancers, the springs of the fourth and fifth wheelsets were also connected by longitudinal balancers. The crew of the locomotive allowed it to pass curves with a radius of 110 m.

The BR 52 could have four types of tenders: K4T26, K4T30, K4T32, K4T34 (the last two digits in the designation correspond to the water supply in m3). At the K4T32 tender, a semi-cylindrical water tank replaced the frame. All tenders were four-axle, the axle boxes of the two-axle tender bogies had roller bearings. Some tenders were equipped with a mode mechanism that regulated the brake pressure depending on the amount of water in the tender.

The total mass of the steam locomotive (without tender) was 86 tons, coupled – 77 tons. The features of the BR 52 were a relatively small area of the grate – 3.92 sq.m and a small volume of the furnace – 6.9 cubic meters. m. This technical solution made it possible to work only on high-grade coals. When using low-grade mixtures, these steam locomotives sharply reduced their thermal performance, which was fully manifested in captured Soviet fuel cells, since Soviet coal was of very poor quality.

The crew of the steam locomotive of the 52 series allowed it to pass curves with a radius of 110 m.

Subsequent steam locomotives of the BR 52 series began to be produced by the Borsig plant from September 1942, and from January 1943 their production begins not only at German locomotive plants, but also at some plants in other countries:

Subsequent steam locomotives of the BR 52 series began to be produced by the Borsig plant from September 1942, and from January 1943 their production begins not only at German locomotive plants, but also at some plants in other countries:

LOFAG, Vienna: 1053 pcs

Henschel, Kassel: 1050 pcs

Schwartzkopff, Berlin: 647 pcs

Krauss-Maffei, Munich: 613 pcs

PRheinmetal-Borsig, Berlin: 542 pcs

Schichau, Elbing: 505 pcs

Maschinenbau und Bahnbedarfs AG, Babelsberg: 400 pcs

DWM Posen, Poznan: 314 units

Krenau, Upper Silesia: 264 units

Maschinenfabrik Esslingen, Esslingen: 250 units

Jung und Jungenthal, Kirchen: 231 units

Skoda, Pilsen: 153 units

Grafenstaden, Strasbourg: 139 units

Since the experimental tender required further development, the first issue was coupled with a tender from BR50 – rectangular on bogies – type K2’2’T26 and rectangular with wheelsets in a frame – type K4T30 of the Vienna plant, known as the “kangaroo”.

1108 steam locomotives are equipped with protection from the cold: boilers, cylinders, steam inlet and feed pipes, compound pumps and the walls of the water tanks of the tenders are insulated with glass wool and covered with casings. A damper is installed on the chimney, which was used in long-term parking, with a drive to the booth by means of a cable.

Military locomotives were completely covered with a bluish-gray “protective” paint (without a scarce varnish).

The light color helped to reveal cracks. They also pursued another goal: road officials should distinguish these cars, and the locomotive brigade should be aware that they were on a military locomotive. On the walls of the booth there were stencils: the series and number of the locomotive; more finely: P – cargo; 56 – five coupling axles, six in total, 15 – average axle load; triangle – individual parts of the locomotive go beyond the gauge of the rolling stock. A line above it – in order to introduce the locomotive into the envelope, it is necessary to remove the extension on the chimney. The red circle, indicating the steel fire box, soon disappeared from the booth. The home point was applied later, at the destination.

BR 52s were numbered from 001 to 7794, with numbers from 1850 to 2027 being given by a steam locomotive with Henshel-built condenser tenders.

In various publications, the number of the last steam locomotive of this series diverges significantly, since after the war a certain number of steam locomotives were produced from previously prepared materials and blanks.