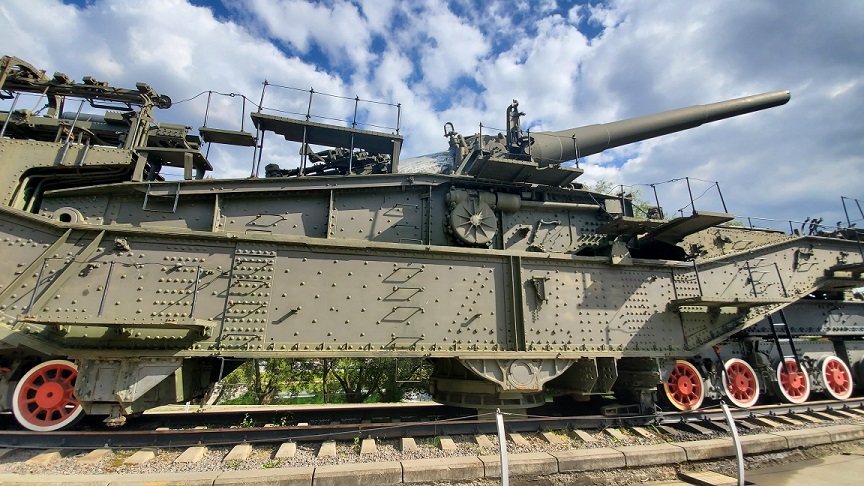

TM-1-14 Soviet 356-mm Railway Artillery Cannon

TM-1-14 Soviet-Railgun

In the mid-20s, the Workers ‘and Peasants’ Red Fleet (RKKF) was only a pitiful shadow of the former fleet of the Russian Empire and in no way could withstand the fleets of potential opponents. It was also not possible to ensure the protection of coastal strategic objects with the help of stationary artillery systems due to the high cost and too high vulnerability of the latter. Against this background, the decision of the Artillery Committee of the Main Artillery Directorate (AK GAU) of the Red Army to create railway artillery installations armed with long-range guns seemed quite logical.

Formed in accordance with this decision in October 1930, the Central Design Bureau of Shipbuilding No. 3 (TsKBS-3) under the leadership of A.G. By March 1931, Dukelsky developed a technical design for a 356-mm railway artillery mount, designated TM-1-14 (sea transporter, type 1, 14-inch caliber).

Such a rapid pace of development of such a rather complex “product” as a railway artillery installation is explained by two circumstances.

First, a significant part of A.G. Dukelsky performed it back in the late 1920s, when he worked as a prisoner in the Special Design and Technology Bureau (OKTB) of the OGPU. Secondly, the 14-inch American railway artillery mount M 1920 M 2, created in 1920 for the US Army and Navy, was “creatively” used as a model.

The main components of the TM-1-14 railway artillery mount were a 356-mm cannon and a railway transporter. By the time the design of the TM-1-14 began, 16 356-mm guns were stored in warehouses, originally intended for four Izmail-class battlecruisers laid down in December 1912 in St. Petersburg. The First World War and the Civil War prevented the completion of these ships, they were eventually dismantled for scrap. In this regard, the use of guns that have become unnecessary to create railway artillery installations provided significant savings in time and money.

The 356-mm gun had a 52-caliber bonded barrel, the shutter was a horizontal piston. The length of the rifled part of the barrel was 14,985 mm; 84 grooves of constant steepness were made in the bore. Cartridge loading was envisaged, the charges consisted of two half-charges. At the design stage of the TM-1-14, all 16 guns were tested. At the very first firing, six guns received the so-called “bloat”. In addition, in all the guns, an insufficient margin of longitudinal strength was found. Therefore, when designing the TM-1-14, lower ballistic data were adopted than those that were specified for ship guns. For example, in the “Izmail” towers, when firing with a charge of 245.7 kg, an armor-piercing projectile of the 1911 model with a mass of 747 kg was supposed to develop an initial speed of 823 m/ s,

The maximum firing range was impressive – 31,000 m, and when firing a high-explosive projectile weighing 512.5 kg, it increased to 51,000 meters. At the same time, the survivability of the barrel was only 150 shots, after which the gun had to be dismantled from the installation and sent to the factory to replace the inner tube. This operation lasted several months and in wartime was fraught with a lot of problems.

The railway conveyor was a massive main beam made of sheet steel, which, through the so-called balancers, rested on the railway bogies. Three types of carts were used.

Two carts of the first type were four-axle motor-driven, they were located at the ends of the conveyor. In front of the conveyor there was a six-axle bogie of the second type (medium), and in the rear part there was a four-axle bogie of the third type (also medium).

The carts had very small dimensions in height (no more than 1250 mm) and length (distance between axles no more than 1500 mm). At the same time, in addition to the calculated static load on the axle, which amounted to 22.5 tons and affected all axles, the axles of the rear bogies were subjected to additional loads during the shot, reaching 8 tons.

On railway transporters, the guns were mounted on machine tools removed from tower mounts made for battlecruisers. The main elements of the machine were two hydraulic recoil brakes (compressors) and an air-hydraulic knurler of an independent type.

When firing at low elevation angles, the braking of the rolling mass at the end of the roll was of particular importance. For this purpose, the knurler was equipped with a check valve with an overrun regulator, which was included in the work at the last 250 mm of travel, and at the last 150 mm, the hydraulic buffers of the compressor took part in braking. As a result, the gun rolled smoothly without impacts at all elevation angles, and the roll-up time was 2 seconds. To increase the rate of fire, opening the lock was possible in the range from -15 ° to – 7 °, and not only when the gun was stationary, but also during vertical guidance.

Guidance in the vertical plane was carried out using two lifting sectors mounted on the sides of the machine. In this case, an electric drive was used with speed control by means of Janie clutches.

Due to the large size of the gun and the significant length of the rollback, which was almost 1.5 m, the designers were forced to raise the axis of the gun trunnions to a height of about six meters above the rails. This ensured firing at a maximum elevation angle of 50 ° without digging a pit under the conveyor, but at the same time did not allow it to “fit” into the railway gauge. For this reason, in the stowed position, the gun with the machine was lowered by 2 meters.

Since the railway artillery mount TM-1-14 was intended primarily for firing at sea targets moving at a sufficiently high speed, it was necessary to provide a wide range of horizontal guidance angles. This requirement was possible only when using a concrete base for firing, on which the main beam of the conveyor was lowered. At the same time, railway carts rolled out from under the conveyor and it got the opportunity to rotate around a vertical axis along a circular shoulder strap of a concrete base.

For each battery of railway installations, which consisted of three guns, a main and a spare firing position was built. The position housed three concrete bases, platforms for transporters, shelters for personnel and everything necessary for the operation of transporters. The first battery was assigned the number six, the transporters for it were presented for delivery in 1932, and at the beginning of 1933, preparations began for the transition of the battery to the Far East. The first of the three echelons of the battery set off on November 3, 1933, and on December 17, that is, a month and a half later, the echelons arrived at their destination station, Pervaya Rechka.

TM-1-14 Soviet-Railgun

By 1935, three more TM-1-14 transporters were manufactured and put into service. They made up battery number 11, the positions for which were equipped on the southern coast of the Gulf of Finland.

It should be noted here that along with firing from a concrete base, the transporters could also fire from wheels. However, to ensure the aiming of the gun in the horizontal plane, it was necessary to build special rounded railway tracks (whiskers), moving along which the conveyor could change the angle of fire.

To control the shooting, a PUS system (fire control devices) was developed. The battery post, made in the form of a collapsible tower, usually housed a six-meter stereoscopic rangefinder and central aiming devices.

The data from the battery post came to the central post, equipped in a special car. Here, the selection and transformation of azimuths and “target-post” distances into azimuth and “battery-target” distances and their transfer to the guns to the receiving devices was carried out. It was also envisaged to individually aim the guns with the help of an optical sight with a sixfold increase.

In addition to the above-mentioned wagon – the central post, the battery included three wagons – shell cellars (one for each gun), three wagons – charging cellars, three wagons of power stations and three wagons of compressor stations. There was also a so-called “mobile base” in the form of a composition of 3-4 cellar cars, 4 cars with fuel and lubricants and camouflage equipment, residential cars and cars equipped for utility rooms. In total, this train had 20 cars and 2 cool cars.

In peacetime, the battery had 331 people, including 16 commanders.

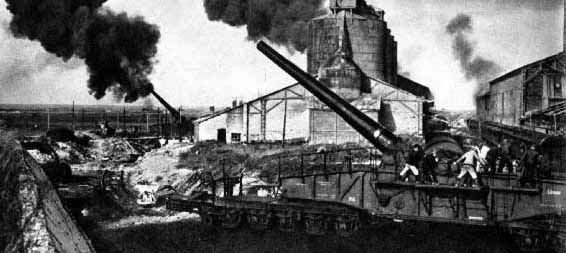

By the beginning of World War II, the Soviet Navy had two three gun batteries TM-1-14: number 6 in the Far East and number 11 in the Baltic. The 6th battery remained in the Far East throughout the war, keeping the Japanese command from making “wrong” decisions. At the same time, the 11th battery was quite actively used in the defense system of Leningrad.

In addition to shelling railway stations and areas where enemy troops were concentrated, the battery fought long-range enemy artillery. And the fact that the shelling of Leningrad was gradually reduced is the great merit of this particular battery.

All six railway installations were withdrawn from service in 1952.